Electric Tricycles, Electric Scooter, Electric Four Wheels Manufacturer

Experienced Electric Transportation Manufacturer in China

Company Overview

Welcome to UCORE Technology Co., Ltd. (UCORE), a subsidiary of Tianjin Xingchang Electric Vehicle Co., Ltd (XINGCHANG), which is dedicated to XINGCHANG’s global market expansion. As a leading manufacturer specializing in the development, production, and sales of electric bicycles, tricycles, four-wheelers, and other eco-friendly transportation solutions.

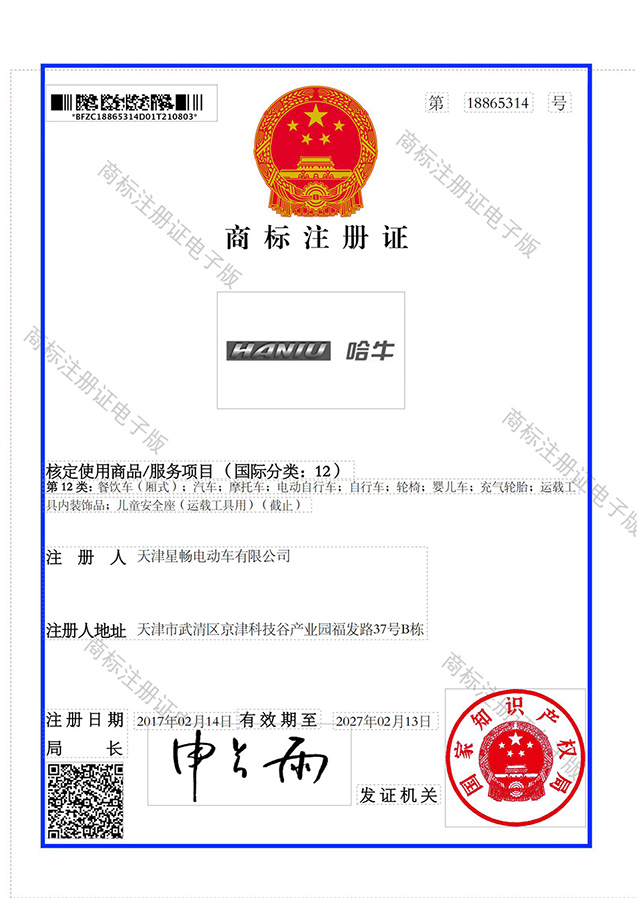

XINGCHANG has earned a strong reputation in China with its brand “哈牛HANIU”. Located in China’s Tianjin Bicycle Manufacturing Base, XINGCHANG invested in 2024 to establish the HANIU Super Factory, covering 200,000 square meters with facilities for motors, wiring, frames, painting, and assembly, achieving a fully integrated production process.

As the global business arm of XINGCHANG, UCORE is committed to providing quality products and complete solutions to our international customers.

Companies Relationship

- Parent Company: Tianjin Xingchang Electric Vehicle Co., Ltd. (Domestic Market)

- Subsidiary: UCORE (Tianjin)Technology Co., Ltd. (Global Market)

- Factory Scale: Covers over 200,000 square meters, with 10+ modern workshops and high-standard automated production lines

- Annual Production Capacity: Over 100,000 electric vehicles

Product Range

Our diverse range of 200+ products is designed to meet the needs of various markets worldwide. Our offerings include:

- Electric Tricycles (E-trikes): Leisure Tricycles, Electric Rickshaw, Cargo Tricycles

- Electric Four-Wheelers (E-quads)

- Electric Scooters (Electric Motorcycles)

- Electric Bicycles (E-bikes)

- Bicycles

- Customized Specialty Vehicles

Workshop

UCORE is equipped with advanced production facilities across 10 specialized workshops for motors, wire harness, frames, spraying and assembly. With an annual capacity exceeding 100,000 units, we ensure efficiency and quality at every step.

- Motor Workshop: Features automated winding machines, magnet placement machines, and other equipment to meet the demands for lead-acid, lithium, and other permanent magnet motors.

- Wire Harness Workshop: Equipped with cutting-edge machines, including terminal crimping and automated cutting equipment, to provide high-quality wiring solutions.

- Frame Workshop: Uses laser cutting, CNC tube bending, and stamping technology to ensure robust and safe frame structures.

- Spraying Workshop: Employs advanced processes like acid washing, phosphating, electrophoresis, and multi-layer coating to ensure a durable, corrosion-resistant finish.

- Assembly Workshop: Responsible for completing the assembly of vehicles, with a comprehensive testing center that includes vibration test benches, suspension test stands, and corrosion test chambers.

Quality Control & Certifications

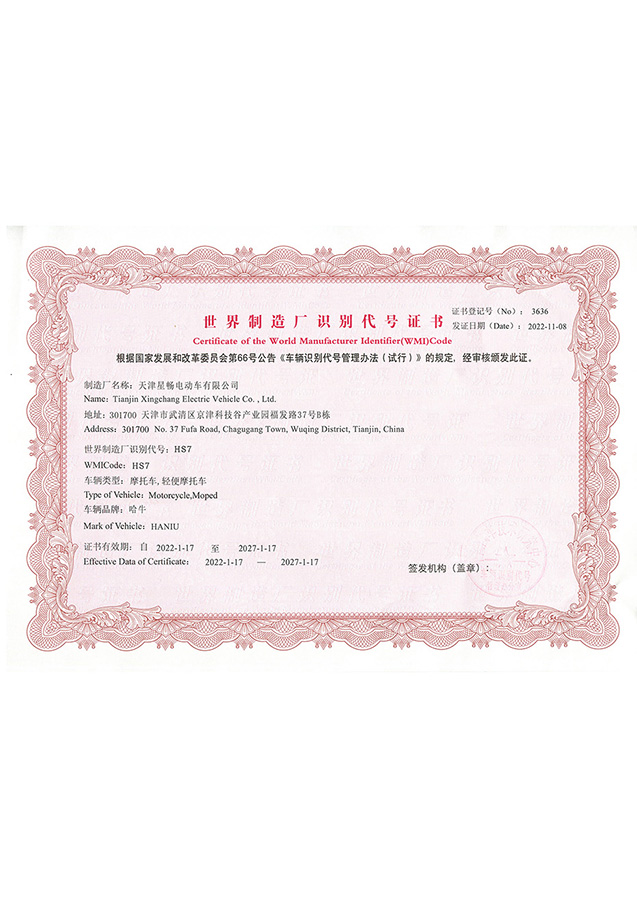

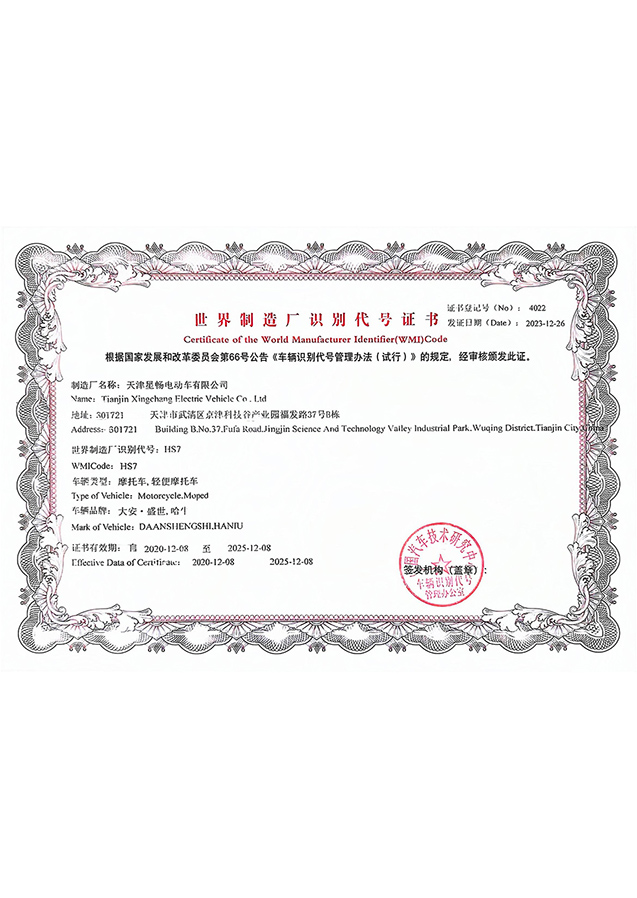

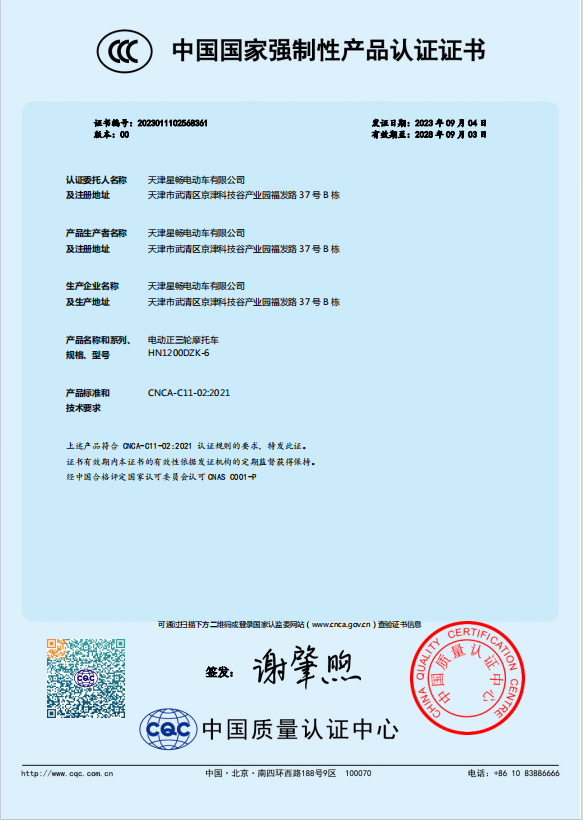

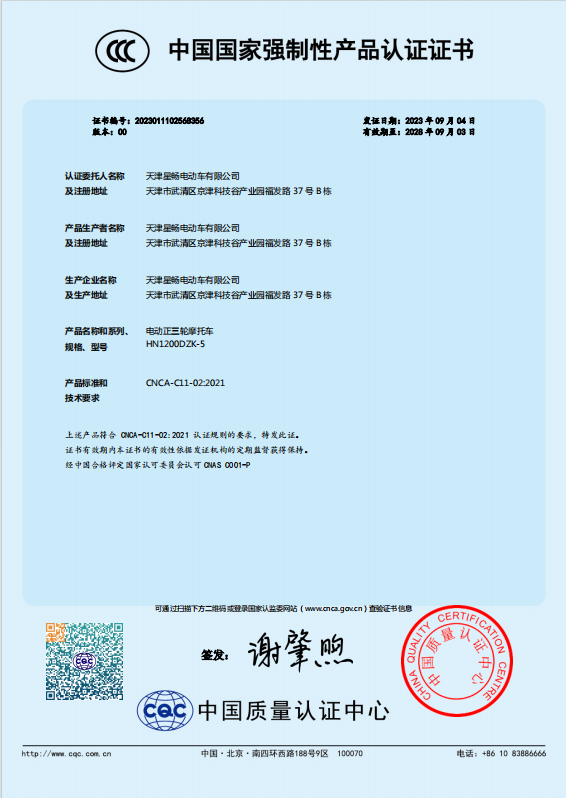

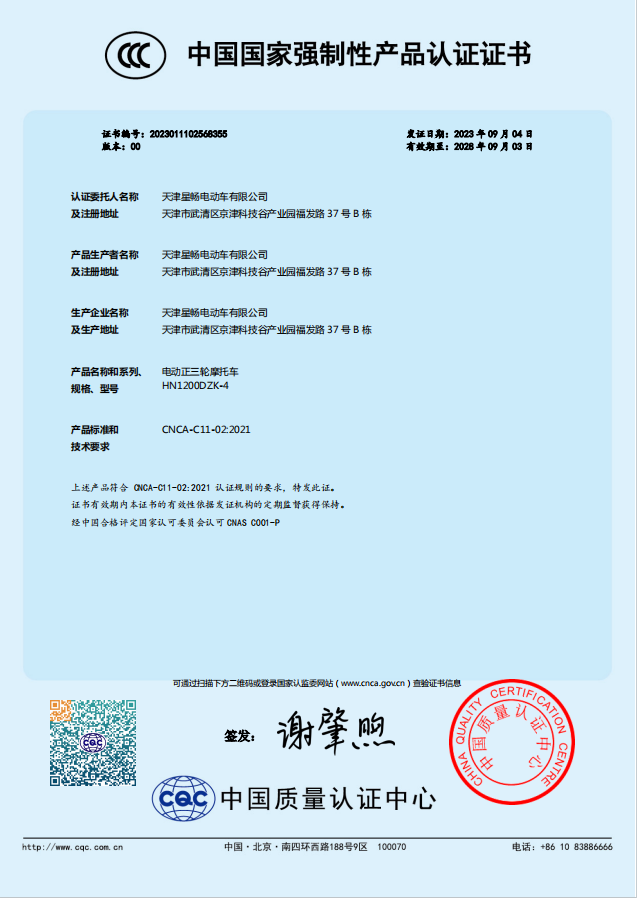

UCORE has established a comprehensive quality management system and obtained several authoritative certifications to ensure high standards in product quality and production. The company has received the WMI (World Manufacturer Identifier) certification, which supports global standards for product tracking and distribution in international markets. Additionally, UCORE is certified under the GB/T19001-2016/ISO 9001:2015 Quality Management System, demonstrating its strict adherence to international standards in production management. These certifications not only reflect the company’s commitment to quality but also provide a reliable guarantee for global customers, enhancing the competitiveness and trustworthiness of its products.

International Market & Export Experience

Xingchang’s products are exported to over 50 countries and regions, with major markets in South America, the Middle East, Africa, Southeast Asia, and Europe. We maintain strong partnerships with reputable importers, distributors, and retailers and are actively expanding our market presence.

Customization Services

To meet the varied requirements of global customers, we offer a range of customization services, including:

- Vehicle design and appearance customization

- Component and feature adjustments

- Custom logo and packaging services

After-Sales Service & Support

We provide comprehensive after-sales support, including professional technical assistance, prompt maintenance response, and spare parts supply and repair training for large clients, ensuring seamless business operations.

Environmental Protection and Sustainability

We are committed to creating a green future by providing eco-friendly transportation solutions.

UCORE places sustainability at the forefront of its mission. We are dedicated to supporting environmental protection by selecting eco-friendly materials and reducing carbon emissions in our production process. As a manufacturer of electric bicycles and tricycles with closed-loop production capabilities, we use high-standard automated equipment to achieve efficient energy use and resource recycling. Our goal is to provide clean, safe transportation options to global consumers, promote green travel, reduce pollution, and make the earth a better place.

Submit Your Request

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you find the item you need.

Call us: +86 18622086554

Email: annyz@ucorebike.com

doris@ucorebike.com